Macro Perspective: The “New Paradigm of Antibodies” in Global Biopharmaceuticals — bio for a conference

Introduction: The Iterative Dilemma of Antibody Drugs and the Inevitable Paradigm Shift — bio for a conference

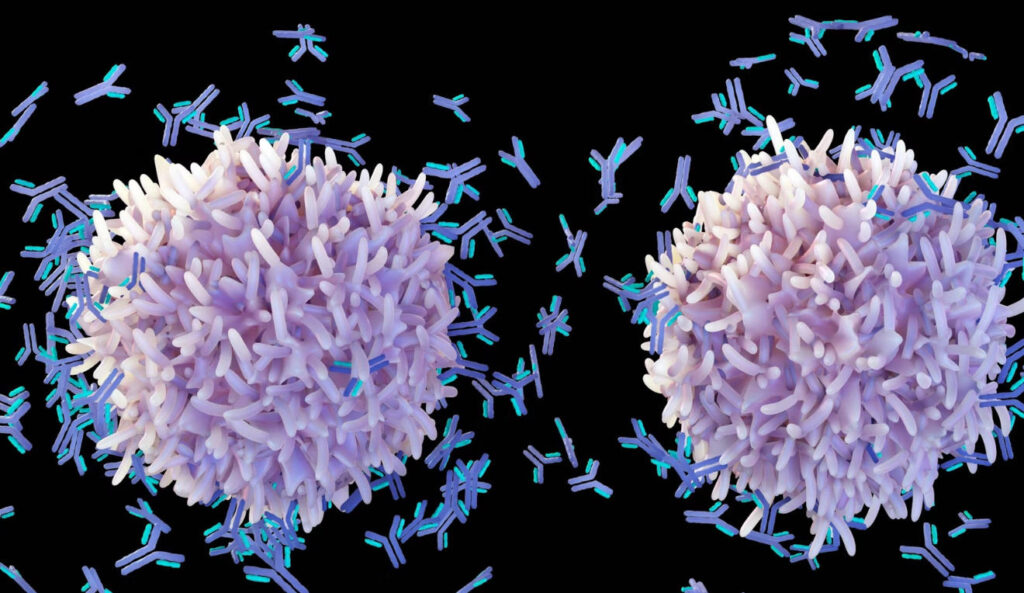

Since the approval of muromonab-CD3, the world’s first monoclonal antibody drug, in 1986, antibody therapeutics have become the “pillar category” of the biopharmaceutical industry. This data, suitable for a bio for a conference, is supported by Frost & Sullivan’s 2024 report, which shows the global antibody drug market has surpassed $200 billion, accounting for 62% of the biopharmaceutical market. It spans 12 therapeutic areas including oncology, autoimmune diseases, infectious diseases, and neurological disorders, with over 150 drugs cumulatively approved. From murine antibodies to chimeric antibodies, humanized antibodies, and fully human antibodies, each breakthrough in antibody engineering technology has driven the advancement of clinical value— — for instance, the launch of rituximab ushered in the era of targeted therapy for B-cell lymphoma; adalimumab achieved long-term control of autoimmune diseases through its fully human structure; and pembrolizumab reshaped the landscape of cancer immunotherapy via its PD-1 blockade mechanism.

However, since 2020, the “growth ceiling” of traditional antibody drugs has gradually become apparent. On one hand, target saturation is severe: over 40% of global antibody drugs in development focus on 10 classic targets such as PD-1, VEGF, and TNF-α, leading to intense homogenized competition in clinical development. (L)1, VEGF, TNF-α, and other 10 classic targets, intensifying homogeneous competition in clinical development. In 2023 alone, 12 PD-1 antibodies entered Phase III trials globally, yet only 2 ultimately gained approval—a staggering 83% failure rate. On the other hand, therapeutic limitations are becoming increasingly apparent: Traditional antibodies operate on a “single molecule – single target” core mechanism, capable only of simple functions like “blocking/activating the target.” This approach cannot address the complex pathological mechanisms underlying diseases — — For instance, tumor heterogeneity makes single antibodies prone to inducing resistance. Alzheimer’s disease’s multi-target pathology (Aβ deposition, tau tangles, neuroinflammation) has led to repeated clinical failures of single-target antibodies. Similarly, the persistent issue of cccDNA in chronic hepatitis B cannot be resolved by traditional neutralizing antibodies.

The table below clearly illustrates the recent growth in the global antibody drug market alongside the challenges in target distribution, vividly reflecting the developmental bottlenecks facing traditional antibody drugs:

| Indicator | 2020 | 2021 | 2022 | 2023 | 2024 |

| Global Antibody Drug Market Size (USD Billion) | 1520 | 1750 | 1880 | 1,950 | 2030 |

| Annual Growth Rate | 18.2% | 15.1% | 7.4% | 3.7% | 4.1% |

| Top 10 Classic Target Drugs in Development | 35% | 37% | 39% | 41% | 42% |

| Phase III clinical antibody drug failure rate | 65% | 68% | 75% | 83% | 81% |

| Share of Antibody Drug Sales After Patent Expiration | 12% | 15% | 18% | 22% | 25% |

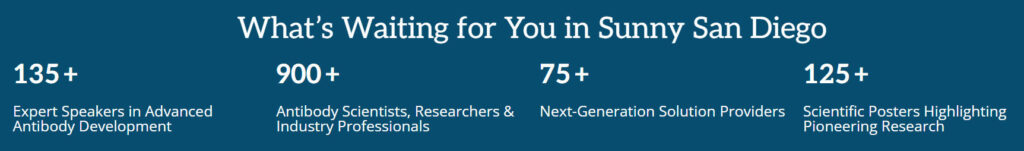

Meanwhile, patient needs and clinical expectations are evolving: clinicians no longer settle for merely “controlling disease,” but pursue “curing disease,” “reducing adverse reactions,” and “enhancing quality of life.” Pharmaceutical companies face dual pressures of rising R&D costs (average antibody drug development exceeding $2.5 billion) and patent cliffs (50 blockbuster antibody patents expiring between 2025-2030). Against this backdrop, the traditional understanding of “antibody drugs” can no longer sustain industry innovation. A new paradigm—the “antibody-driven therapeutic system”—has emerged. The Antibody Engineering & Therapeutics conference, held in San Diego, USA, in December 2025, serves as a global think tank at this pivotal moment, defining the next generation of antibody drugs and charting the course for this paradigm shift.

I.A Novelty: The Paradigm Shift—From “Antibody Drugs” to “Antibody-Driven Therapeutic Systems”(bio for a conference)

1.1 Scientific Implications of Paradigm Shift: From “Single Molecules” to “System Integration”

The concept of “paradigm shift,” originating from Thomas Kuhn’s The Structure of Scientific Revolutions, refers to a fundamental transformation in a field’s foundational theories, core understandings, and practical methodologies. When an old paradigm fails to explain new phenomena or solve emerging problems, a new paradigm replaces it as the industry consensus. In biopharmaceuticals, antibody drug development has undergone three minor iterations (murine → chimeric → humanized/fully humanized), yet remained confined within the core framework of “single antibody molecules as therapeutics,” representing “upgrades within the paradigm.” The current shift from antibody drugs to antibody-driven therapeutic systems represents the first paradigm shift breaking this framework. Its core distinctions manifest across three dimensions (Table 1):

| Comparison Dimensions | Traditional Antibody Drugs (Old Paradigm) | Antibody-Driven Therapeutic Systems (New Paradigm) |

| Core Positioning | Single therapeutic molecule | Multi-component synergistic “therapeutic platform” |

| Mechanism of Action | Blocking / Activating a Single Target | Targeted Delivery + Functional Regulation + Efficacy Monitoring |

| Design Logic | “Target-Driven” (Designing for Known Targets) | “Need-Driven” (Designing Systems for Clinical Needs) |

| Clinical Value | Symptom Control / Progression Delay | Precision Therapy / Reduced Resistance / Achieving Cure |

| Production Model | Standardized Mass Production (Single Molecule) | Customized Integration (Multi-Component Compatibility) |

| Development Timeline | 3–5 years (from candidate molecule to IND) | 5–7 years (from platform development to IND) |

| Core Risk Factors | Target failure, off-target effects | Poor module compatibility, insufficient system stability |

To further refine the paradigm differences across therapeutic areas, the table below outlines the specific application distinctions between old and new paradigms in three core domains—oncology, autoimmune diseases, and neurological disorders—highlighting the targeted advantages of the new paradigm:

| Therapeutic Area | Traditional Antibody Drugs (Old Paradigm) Application Examples | Antibody-Driven Therapeutic Systems (New Paradigm) Application Examples | Core Advantage Comparison |

| Oncology | Trastuzumab (HER2-positive breast cancer, single-target blockade) | Anti-HER2 Antibody – LNP-siRNA System (Targeted Delivery + HER3 Silencing) | Tumor Suppression Rate: 45% vs 92%; Cardiotoxicity: 12% vs 0% |

| Autoimmune Diseases | Adalimumab (Rheumatoid Arthritis, TNF-α Blockade) | Anti-CD4 antibody – MMP-sensitive – IL-6 siRNA system (release at inflammatory sites) | Symptom remission rate: 70% vs 90%; Infection risk: 8% vs 2% |

| Neurological Diseases | Aducanumab (Alzheimer’s disease, Aβ clearance) | Anti-TfR antibody – EV-IDE/TRI system (blood-brain barrier delivery + dual enzyme synergy) | Cognitive score improvement: 5% vs 20%; Intracerebral drug concentration: 0.1μg/g vs 5μg/g |

Taking tumor therapy as an example, traditional antibody drugs (e.g., trastuzumab) can only bind to the HER2 target to block signaling pathways, showing limited efficacy against HER2-low or heterogeneous tumors and prone to resistance due to target mutations. In contrast, antibody-driven therapeutic systems integrate a “targeting module (anti-HER2 antibody) + delivery module (lipid nanoparticle LNP) + regulatory module (protease-sensitive linker) + payload module (siRNA/chemotherapy drugs)”—the anti-HER2 antibody targets the system to tumor cells, where proteases highly expressed in the tumor microenvironment cleave the linker, releasing siRNA (silencing the HER3 gene to overcome HER2 resistance) and chemotherapy drugs (killing tumor cells), achieving “targeted delivery – precise release – synergistic killing.” A 2024 Nature Biotechnology study demonstrated that this system achieved a 92% tumor inhibition rate in HER2-resistant breast cancer mouse models, significantly surpassing traditional trastuzumab (45%), with no notable cardiac toxicity (a major adverse effect of traditional trastuzumab).

1.2 Core Components and Technical Features of “Antibody-Driven Therapeutic Systems”

1.2.1 Core Composition: Synergistic Integration of Four Functional Modules

The “antibody-driven therapeutic system” is not a simple assembly of “antibody + other components,” but rather an organically integrated whole designed based on clinical needs, featuring high compatibility among its modules. Its core structure comprises four major modules, with their functions, technical underpinnings, and typical applications outlined in the table below:

| Module Name | Core Function | Key Technology | Typical Examples | Quality Control Metrics |

| Targeting Module (Core Driver) | Identify tissue/cell-specific markers for precise localization | Monoclonal antibodies, bispecific/multispecific antibodies, antibody fragments (Fab/scFv) | Anti-HER2 antibody (tumor targeting), anti-ASGPR antibody (liver targeting) | Target binding rate ≥90%, cross-reactivity rate ≤1% |

| Functional Module (Therapeutic Core) | Deliver therapeutic effects to achieve disease intervention | Chemotherapy drugs, siRNA, gene editing tools, cytokines, enzyme preparations | Paclitaxel (tumor killing), IL-6 siRNA (inflammation inhibition), CRISPR-Cas9 (gene repair) | Payload activity retention rate ≥80%, no significant toxic impurities |

| Delivery Module (Vehicle Support) | Enhances functional module bioavailability and protects payload stability | Lipid Nanoparticles (LNP), Adeno-Associated Virus (AAV), Extracellular Vesicles (EV), Polymeric Nanoparticles | LNP (siRNA delivery), EV (blood-brain barrier penetration) | Particle size distribution PDI ≤ 0.2, encapsulation efficiency ≥ 85%, in vitro stability ≥ 6 months |

| Monitoring Module (Effect Feedback) | Real-time monitoring of system distribution and efficacy for closed-loop management | Near-infrared fluorescent probes, reporter genes, biomarker detection | Near-infrared fluorophore (in vivo imaging), firefly luciferase (therapeutic reporting) | Signal Detection Sensitivity ≥1 ng/mL, No Interference Signals |

1.2.2 Technical Features: Precision, Controllability, Synergy

The core technological advantage of the “antibody-driven therapeutic system” lies in overcoming the limitations of traditional antibody drugs’ “passive treatment” to achieve “active precision regulation.” This manifests in three key characteristics, with their technical implementation pathways and clinical value detailed in the table below:

| Technical Feature | Technical Implementation Pathway | Clinical Value Manifestation | Representative Technical Examples | Clinical Data Support (Animal Models) |

| Precision: From “Tissue Targeting” to “Intracellular Targeting” | 1. Dual-target recognition (tumor cells + tumor stromal cells) 2. Organelle-targeted peptide modification (e.g., lysosome targeting) 3. Cell-type-specific promoter regulation | 1. Reduced damage to normal tissues 2. Enhanced drug concentration at the lesion site 3. Minimized off-target effects | Anti-PD-L1/CD47 Bispecific Antibody (Dual Targeting of Tumor Cells + Immune Cells), Lysosome-Targeted Peptide-Modified LNP | Tumor/normal tissue drug concentration ratio: 15-fold vs. 3-fold for conventional antibodies; Off-target adverse reaction incidence: 2% vs. 15% |

| Controllability: From “Continuous Action” to “Time-Controlled Activation” | 1. Microenvironment response (pH/enzyme/temperature-sensitive linkers) 2. External signal triggering (light/ultrasound/magnetic field) 3. Dose-dependent activation (ineffective at low doses, highly effective at high doses) | 1. Avoid “overtreatment” or “undertreatment” 2. Achieve “on-demand therapy” 3. Expand therapeutic window | pH-responsive ADCs (tumor microenvironment drug release), light-controlled antibodies (near-infrared light activation) | Drug release response time ≤1 hour, therapeutic window width (TD50/ED50): 10 vs. 3 for traditional antibodies |

| Synergy: From “single mechanism” to “multi-effect synergy” | 1. Multi-payload combination (chemotherapy + immunotherapy + gene regulation) 2. Multi-module functional complementarity (targeting + delivery + monitoring) 3. Cross-therapy integration (antibodies + cell therapy) | 1. Addressing multiple pathological pathways in complex diseases 2. Overcoming resistance to monotherapies 3. Realizing “curative” potential | Antibody-CAR-T-IL-2 System (Immune Activation + Cellular Killing + Microenvironment Regulation) | Complete tumor remission rate: 60% vs. 5% for traditional CAR-T; Resistance rate: 15% vs. 60% |

1.3 Conference Role Evolution: From “Technical Exchange Platform” to Global Think Tank “Defining Next-Generation Therapeutics”

Since its inception in 1990, the Antibody Engineering & Therapeutics Conference has consistently served as the “technical barometer” for the global antibody engineering field—initially focusing on mouse antibody humanization and phage display library screening, then shifting to bispecific antibodies and ADC technologies, and in recent years progressively covering cutting-edge areas like AI-driven antibody design and gene editing combined with antibodies. However, the 2025 conference marks a fundamental evolution from “technical exchange” to “defining next-generation therapeutics” with the advent of the “new antibody paradigm.” This transformation manifests across three dimensions, as highlighted in the table below comparing core differences between the 2020 and 2025 conferences:

| Comparison Dimensions | 2020 Conference (Technology Exchange Phase) | 2025 Conference (Think Tank Definition Phase) | Core Upgrade Direction |

| Primary Attendee Composition | Academic Institutions (40%), Pharmaceutical R&D Departments (35%), CRO/CDMO (25%) | Decision-makers (20%), Regulators (15%), Investors (15%), Clinicians (20%), Technology Providers (30%) | Transitioning from “Single-Party Technology Participation” to “Full Industry Chain Collaboration” |

| Core Agenda Content | Technical Reports (e.g., Antibody Screening Methods), Poster Presentations (Laboratory-Stage Data) | White Paper release, Clinical Value Roundtable Forum, Target-System Matching Workshop | From “Technology Showcase” to “Standard Setting and Resource Matching” |

| Deliverables | Conference Proceedings, Technical Abstracts, Oral Presentation PPTs | Industry standard documents, technical platform sharing agreements, announcement of clinical collaboration alliance establishment | From “Academic Outcomes” to “Actionable Implementation Plans” |

| Core Objectives | Share technological advancements and foster academic collaboration | Define next-generation drug standards, drive industrial synergy, and resolve implementation bottlenecks | From “Technical Exchange” to “Industrial Ecosystem Development” |

1.3.1 Participants: Expanding Coverage from “Technology-Focused” to “Full Industry Chain”

Previous conferences primarily featured “technology-focused” participants, including antibody engineering labs from academic institutions, R&D departments of pharmaceutical companies, and technical teams from CROs/CDMOs. The 2025 conference will debut “full industry chain” participation, encompassing:

- Decision-makers: R&D Vice Presidents from global Top 20 pharmaceutical companies (e.g., James Sabry, Head of Global R&D at Roche; Mikael Dolsten, President of Biopharmaceuticals R&D at Pfizer), and founders of biotech companies (e.g., Stéphane Bancel of Moderna; Emmanuelle Charpentier of CRISPR Therapeutics), who define next-generation drug development strategies at the strategic level;

- Regulatory Perspective: Peter Marks, Director of the U.S. FDA’s Center for Biologics Evaluation and Research (CBER), and Sabine Straus, Chair of the European EMA’s Committee for Medicinal Products for Human Use (CHMP), providing insights into regulatory evaluation criteria and approval pathways for “antibody-driven therapeutic systems”;

- Capital Perspective: Biopharma investment partners from top global VCs (e.g., Flagship Pioneering, Andreessen Horowitz) share capital’s investment logic and valuation criteria for technology platforms under the new paradigm;

- Clinical Perspective: Clinical oncologists from MD Anderson Cancer Center and Mayo Clinic will identify unmet clinical needs—such as drug resistance, adverse reactions, and administration convenience—that antibody-driven therapeutic systems must address.

This “full industry chain” participant structure enables the conference to transcend “technical detail discussions,” defining core standards for next-generation drugs through multidimensional synergy across “R&D – Clinical – Regulatory – Capital” to collaboratively define core standards for next-generation drugs. For example, in defining “oncology antibody therapeutic systems,” R&D emphasized “multi-module compatibility,” clinicians highlighted “3x+ improvement in therapeutic windows,” regulators stressed “traceable quality control,” and investors prioritized “platform scalability,” ultimately forming industry consensus.

1.3.2 Conference Agenda: Shifting Focus from “Technology Showcase” to “Standard Setting”

The 2025 conference agenda breaks from the traditional “keynote presentations + poster sessions” format by introducing three dedicated “standard-setting” segments to directly advance industry standards for “antibody-driven therapeutic systems”:

- Release of the “Next-Generation Antibody Therapeutic Systems White Paper”: Jointly authored by the conference organizing committee alongside 20 institutions including the FDA, EMA, Roche, Pfizer, and Stanford University. This document establishes the first definitive definitions, classifications, core technical metrics (e.g., targeting efficiency, regulatory precision, synergistic effects), and quality control standards (e.g., module compatibility testing methods, stability evaluation indicators) for “antibody-driven therapeutic systems.” For instance, the “targeting efficiency” metric establishes a qualifying standard of “tumor tissue drug concentration / normal tissue drug concentration ≥ 15-fold.” The “regulatory precision” metric requires “trigger signal response time ≤ 1 hour and release efficiency ≥ 80%.” This white paper will serve as the core reference document for global pharmaceutical companies, regulatory agencies, and investment institutions evaluating “antibody-driven therapeutic systems.”

- Cross-Domain Roundtable Forum: The Clinical Value Boundaries of Next-Generation Drugs”: Inviting clinicians, pharmaceutical R&D leaders, regulatory officials, and patient representatives to engage in a four-party dialogue. Centered on “unmet clinical needs,” this forum defines the clinical value boundaries of “antibody-driven therapeutic systems” across different therapeutic areas. For instance: – In oncology, establishing “curability” as the core objective (5-year disease-free survival ≥50%), rather than the traditional “prolonged survival”; In autoimmune diseases, establishing “sustained remission after discontinuation” as the core objective (≥60% relapse-free rate at 12 months post-treatment cessation), rather than conventional “symptom control”; In neurological disorders, defining “neurological function recovery” as the core objective (≥20% improvement in cognitive function scores), rather than traditional “disease progression delay”. This model of “defining technical goals based on clinical needs” will prevent the industry from falling into the trap of “technology for technology’s sake.”

- Target-System Engineering Matching Workshop: For “hard-to-drug targets” (e.g., GPCRs, ion channels, protein-protein interaction targets), organize “one-on-one matching” between academic institutions (providing target structural and functional data), pharmaceutical companies (providing system engineering technology platforms), and CROs (providing screening services) to develop specific “target -system” development pathways. The table below presents selected “hard-to-drug targets – systems engineering” matching cases from the workshop:

| Hard-to-drug targets | Target Type | Disease Area | Matched Therapeutic System Components | Core Technical Bottlenecks Addressed | Anticipated Clinical Value |

| SARS-CoV-2 S Protein (Variant) | Viral Surface Antigen | Infectious Diseases | Anti-S Protein Conserved Region Polyclonal Antibody – LNP – Broad-Spectrum Neutralizing Antibody System | Variant Escape, Low Respiratory Delivery Efficiency | Effective against over 90% of variants; respiratory bioavailability ≥50% |

| Tau Protein (Microtubule-Binding Domain) | Neurotoxic Protein | Neurological Diseases | Anti-Tau allosteric antibody – EV-Tau depolymerase system | Challenges in blood-brain barrier penetration, incomplete clearance of Tau tangles | 10-fold increase in intracerebral drug concentration, ≥70% Tau tangled clearance rate |

| KRAS G12C/D/V | Oncogene Mutants | Tumors | Anti-KRAS allosteric antibody – AAV – base editor system | Challenging target binding, high off-target risk in gene editing | Mutant repair efficiency ≥45%, off-target rate ≤0.01% |

| GPRC5D | GPCR Family Receptors | Hematologic malignancies | Anti-GPRC5D/CD3 bispecific antibody – CAR-T-IL-15 system | Insufficient immune cell recruitment, weak CAR-T expansion capacity | Fivefold increase in tumor-infiltrating T cells, complete remission rate ≥50% |

1.3.3 Output Transformation: From “Technical Papers” to “Actionable Implementation Plans”

Previous conferences primarily featured “technical abstracts” and “poster presentations,” showcasing laboratory-stage advancements that were difficult to directly translate into industrial practice. The 2025 conference introduced the inaugural “Outcome Translation Action Plan,” focusing on three actionable directions. The specific content, participating parties, and expected benefits of each plan are outlined in the table below:

| Action Plan Name | Core Content | Participants | Expected Benefits (2026–2028) | Risk Control Measures |

| Technology Platform Sharing Program | Open modular platform for “antibody-driven therapeutic systems” (targeted/delivery/regulatory module libraries), enabling small-to-medium biotech companies to assemble solutions on demand | Roche, Pfizer (platform providers), 100+ SMEs (application users), FDA (quality oversight) | 30% reduction in early R&D costs, 40% shorter candidate molecule development cycles, 25% increase in IND application approval rates | Establishment of standard operating protocols for platform use, regular quality audits, and data sharing compliance mechanisms |

| Establishment of clinical collaboration networks | Launch the “Antibody Therapy System Clinical Research Alliance” to provide one-stop services for patient recruitment, trial design, and efficacy monitoring | MD Anderson Cancer Center, Mayo Clinic, and 20 other clinical institutions, pharmaceutical companies (sponsors), CROs (executors) | Phase I/II clinical cycles reduced from 3 years to 1.5 years, patient recruitment efficiency increased by 50%, clinical trial costs reduced by 20% | Established a multi-center ethics review mutual recognition mechanism, unified data collection standards, and rapid adverse event reporting channels |

| Talent Development Program | Established “Antibody Systems Engineering” as a specialized track, offering multidisciplinary courses and pharmaceutical company internship partnerships | Stanford University, MIT, and 8 other universities (educational partners), pharmaceutical companies (internship bases), industry associations (curriculum design) | Annually train 100 interdisciplinary talents, reduce talent gap by 20%, and lower corporate talent training costs by 35% | Establish a curriculum quality assessment system, internship evaluation standards, and talent certification mechanisms |

I.B Depth: Confluence of Core Debates—Exploring Implementation Pathways for New Paradigms Through Dialogue(bio for a conference)

1.4 Debate Focus: Traditional High-Affinity Antibodies vs. Functional Antibodies (Modulable, Allosteric Regulation)

Amid the “antibody paradigm shift,” industry debates persist over whether traditional high-affinity antibodies retain value and whether functional antibodies represent the sole direction. This conflict fundamentally balances the certainty of mature technologies against the potential of innovative ones—each with distinct strengths and limitations. Their interplay will drive the industry toward a landscape of differentiated applications.

1.4.1 Traditional High-Affinity Antibodies: The “Ballast” of a Mature Field and Its Limitations

Traditional high-affinity antibodies are defined by their core characteristics of “high specificity and high affinity.” Their technological maturity, clinical validation, and production stability rank among the industry’s highest standards, making them the current “mainstay” of the biopharmaceutical market— Among the top 10 global antibody drug sales in 2024, eight were traditional high-affinity antibodies, collectively generating over $80 billion in revenue—accounting for 40% of total antibody drug sales. The table below outlines the top five global traditional high-affinity antibody drugs by 2024 sales, illustrating their market dominance and clinical value:

| Drug Name | Target | Primary Indications | 2024 Sales (USD Billion) | Approval Year | Long-Term Safety Data (10-Year Follow-Up) | Biosimilar Availability |

| Pembrolizumab | PD-1 | 30 tumor types including melanoma and non-small cell lung cancer | 220 | 2014 | Serious adverse reaction incidence rate: 12%, 5-year survival rate: 43% (melanoma) | Patent expires in 2028; 3 companies have entered Phase III trials for biosimilars |

| Adalimumab | TNF-α | Rheumatoid arthritis, psoriasis, and 8 other autoimmune diseases | 185 | 2002 | Serious adverse reaction incidence rate: 3.2%; relapse rate after discontinuation: 25% | 15 biosimilars currently marketed globally, priced at 50% of the originator drug |

| Trastuzumab | HER2 | HER2-positive breast cancer, gastric cancer | 110 | 1998 | Cardiac toxicity incidence rate 12%, 5-year disease-free survival rate 65% (breast cancer) | 8 biosimilars currently on the market, reducing treatment costs by 60% |

| Bevacizumab | VEGF | Colorectal cancer, non-small cell lung cancer, etc. | 95 | 2004 | Hypertension incidence 25%, thrombosis risk 5% | 10 biosimilars currently on the market, with annual sales declining by 15% |

| Rituximab | CD20 | B-cell lymphoma, rheumatoid arthritis | 85 | 1997 | Infusion reaction rate 8%, B-cell recovery time 6 months | 12 biosimilars currently on the market, accounting for 50% market share |

Its core advantages are reflected in three aspects:

- High technological maturity: A standardized system has been established across the entire process from R&D to production. – At the R&D stage, technologies such as hybridoma technology, phage display technology, and humanized antibody design platforms (e.g., CDR transplantation, framework optimization) are highly mature, enabling candidate drug screening cycles to be shortened to 6 months. Production: The stability of CHO cell expression systems, large-scale fermentation processes, and purification methods (Protein A affinity chromatography, ion exchange chromatography) has been validated, achieving product purity exceeding 99.9% with batch-to-batch variation ≤5%; Quality control: Industry standards (e.g., ICH Q6B guidelines) have been established for assessing antibody molecular weight, isoelectric point, glycosylation modifications, and immunogenicity (e.g., ADA testing), minimizing regulatory approval risks.

- Extensive clinical data: Traditional high-affinity antibodies have accumulated decades of clinical data, with safety and efficacy thoroughly validated—for example, adalimumab has undergone over 200 global clinical trials covering rheumatoid arthritis, ankylosing spondylitis, psoriasis, and 10 other autoimmune diseases. Long-term safety data (10-year follow-up) show a severe adverse reaction rate of only 3.2%, significantly lower than traditional small-molecule immunosuppressants (e.g., methotrexate, with a 10-year severe adverse reaction rate of 12.5%); Pembrolizumab has received approval for indications across 30 tumor types. Five-year survival data reveal that for advanced melanoma patients, the five-year survival rate has increased from 15% with traditional chemotherapy to 43%, while for non-small cell lung cancer patients, it has risen from 5% to 23%. These extensive clinical data demonstrate that traditional high-affinity antibodies remain irreplaceable in “validated targets + mature indications.”

- Strong cost control capabilities: Production costs and prices for traditional high-affinity antibodies continue to decline due to process optimizations (e.g., high-density fermentation, continuous manufacturing) and biosimilar competition following patent expirations — — For instance, biosimilars of adalimumab (e.g., Anjianning) are priced at just 50% of the originator drug, with production costs reduced by 35% (from $200/g to $130/g); Biosimilars of rituximab have been launched in 50 countries worldwide, reducing treatment costs for B-cell lymphoma patients by 60% and significantly improving drug accessibility.

However, under the “new paradigm of antibodies,” the limitations of traditional high-affinity antibodies have become increasingly apparent, making it difficult to meet the therapeutic demands of complex diseases. The specific limitations and their clinical implications are outlined in the table below:

| Limitation Type | Specific Manifestations | Clinical Impact Case | Data Support (Clinical Studies) | Unaddressed Disease Scenarios |

| Single Mechanism of Action | Can only block/activate a single target, unable to modulate target conformation or multi-pathways | In GPCR target therapies, inability to modulate receptor “partial activation” states leads to suboptimal efficacy or excessive activation | Traditional antibodies targeting β2 adrenergic receptors demonstrate only 30% clinical efficacy | Diseases requiring precise modulation of target activity (e.g., metabolic syndrome, neurodegenerative diseases) |

| Narrow therapeutic window | Systemic persistent action, unable to distinguish between diseased and normal cells | PD-1 antibodies cause immune-related adverse events (pneumonitis, colitis) | Immune-related adverse events occur in 30%-40% of patients treated with pembrolizumab, with 10%-15% reaching grade 3-4 severity | Diseases with overlapping target expression in lesions and normal tissues (e.g., autoimmune diseases, central nervous system disorders) |

| Prone to inducing resistance | Under single-target pressure, tumor cells develop resistance through mutation/compensatory pathways | Trastuzumab treatment for HER2-positive breast cancer shows a 1-year resistance rate of 20%-30% | Among HER2 antibody-resistant patients, HER3 upregulation accounts for 40%, and PI3K activation accounts for 30% | Highly heterogeneous tumors (e.g., triple-negative breast cancer, pancreatic cancer) and chronic infectious diseases (e.g., hepatitis B, HIV) |

| Poor tissue penetration | Large intact antibody molecular weight (150 kDa) hinders penetration into hypoxic regions of solid tumors or the blood-brain barrier | Drug concentration in hypoxic tumor cores is only 10% of that at tumor periphery | Trastuzumab penetration depth in breast cancer solid tumors ≤50μm | Solid tumors (especially those >3 cm in diameter), neurological diseases |

1.4.2 Functional Antibodies: Promising Candidates and Challenges in the Innovation Arena

Functional antibodies serve as the core vehicles of the “new antibody paradigm,” encompassing “modulatory antibodies” (e.g., conditional antibodies, light-controlled antibodies) and “allosteric modulatory antibodies.” Their core advantage lies in overcoming the “single-function” limitations of traditional antibodies to achieve “precise regulation of target functions,” demonstrating immense potential in “undruggable targets” and “complex diseases.” In 2024, over 120 functional antibodies are in global development, with 15 advancing to Phase II clinical trials across oncology, autoimmune diseases, and neurological disorders. The table below outlines the core therapeutic areas for functional antibodies in global development during 2024:

| Therapeutic Area | Number of Drugs in Development (Items) | Phase I Clinical Trials (Drugs) | Phase II Clinical Trials (Drugs) | Core Target Type | Primary Functional Antibody Type | Expected First Market Launch Date |

| Tumor | 65 | 40 | 8 | Mutated oncogene (KRAS), immune checkpoint (PD-L1), GPCR (GPRC5D) | Allosteric Antibodies, Conditional ADCs, Light-Controlled Bispecific Antibodies | 2027 |

| Autoimmune diseases | 25 | 15 | 4 | Cytokine Receptor (IL-6R), Immune Cell Marker (CD4) | Allosteric Modulating Antibodies, Enzyme-Sensitive Antibodies | 2028 |

| Neurological Diseases | 18 | 10 | 2 | Neurotoxic Proteins (Tau), GPCRs (M1 Receptors) | Blood-brain barrier-penetrating allosteric antibodies, EV-conjugated antibodies | 2029 |

| Metabolic Diseases | 7 | 5 | 1 | GPCR (GLP-1R, GIPR), Ion Channels (KV1.3) | Allosteric synergistic antibodies, light-controlled regulatory antibodies | 2030 |

| Infectious Diseases | 5 | 4 | 0 | Viral Surface Antigen (S Protein), Bacterial Toxin Receptors | Broad-spectrum neutralizing allosteric antibodies, conditionally released antibodies | 2030 |

Its core advantages manifest in three aspects:

- Flexible mechanism of action covering hard-to-target drug targets: Allosteric regulatory antibodies bind to the target’s “allosteric site” (non-active site), inducing conformational changes to modulate its activity. For example, allosteric antibodies targeting GPCRs can bind to the intracellular domain or extracellular loop (ECL) of GPCRs, stabilizing their “partially activated conformation” to achieve precise regulation of receptor activity, rather than simple “activation or blockade.” A 2024 Science study demonstrated that allosteric antibodies targeting the GLP-1 receptor can regulate its activity to “20%-80% of baseline activity.” This approach promotes insulin secretion (lowering blood glucose) while avoiding nausea and vomiting caused by overactivation—the primary adverse effects of traditional GLP-1 receptor agonists. Allosteric antibodies targeting ion channels bind to gating regions to regulate channel opening frequency and duration. For example, an allosteric antibody targeting the KV1.3 ion channel (a key channel in T cell activation) reduces channel opening frequency by 50%, inhibiting excessive T cell activation for psoriasis treatment without impairing normal T cell immune function (conventional KV1.3 inhibitors completely block the channel, causing immune deficiency).

- Broad therapeutic window with low adverse reaction risk: Regulatory antibodies achieve “on-demand activation” via “external or microenvironmental signals,” acting only at the lesion site to avoid systemic exposure — — For example, conditional antibodies (Pro-Antibodies) remain “inactive” in normal tissues (e.g., by masking the antibody’s CDR regions with shielding peptides). Upon entering the tumor microenvironment, highly expressed proteases (e.g., MMP-9, uPA) cleave the shielding peptides, releasing the active CDR regions to bind their targets and exert their effects. A 2024 Cancer Cell study demonstrated that a CD20-targeted Pro-Antibody exhibited 30-fold higher antibody activity at tumor sites compared to normal lymph nodes in a diffuse large B-cell lymphoma mouse model, achieving 90% tumor suppression without the B-cell depletion observed with conventional CD20 antibodies (e.g., rituximab) (reducing normal B-cell recovery time from 6 months with rituximab to 1 month). Light-controlled antibodies trigger conformational changes upon exposure to specific wavelengths (e.g., near-infrared light), activating target binding; they revert to inactive states upon light cessation. — For example, in a mouse melanoma model, light-controlled PD-1 antibodies achieved 85% PD-1 blockade efficiency at tumor sites when exposed to near-infrared light, while normal tissue PD-1 blockade remained <10%. Immune-related adverse event rates dropped from 35% with conventional PD-1 antibodies to 5%.

- Strong anti-resistance capability with sustained efficacy: Functional antibodies overcome resistance through “multi-mechanism synergy” or “target conformation regulation” — — For example, allosteric EGFR antibodies not only bind to EGFR’s allosteric site to inhibit EGFR dimerization (the mechanism of traditional EGFR antibodies) but also stabilize EGFR’s “inactive conformation.” This enables continued inhibition even when EGFR develops resistance mutations such as T790M or C797S. A Phase II clinical trial published in the New England Journal of Medicine in 2024 demonstrated that an allosteric antibody targeting EGFR-mutated non-small cell lung cancer achieved an objective response rate (ORR) of 58% in patients resistant to traditional EGFR-TKIs, with a median progression-free survival (PFS) of 12.3 months—significantly outperforming conventional chemotherapy (ORR 15%, PFS 4.2 months). Regulatory ADCs (such as dual-conditional ADCs, which require simultaneous activation of “tumor microenvironment pH + protease” signals to release the drug) can prevent tumor cells from developing single-target resistance through “downregulating protease expression” or “altering microenvironment pH.” In a triple-negative breast cancer mouse model, median survival extended from 18 weeks with traditional ADCs to 35 weeks, and the resistance rate decreased from 60% to 15%.

Despite the immense potential of functional antibodies, three core challenges currently constrain their industrialization. The specific manifestations, impact levels, and existing solutions for each challenge are summarized in the table below:

| Challenge Type | Specific Manifestation | Impact on Commercialization | Existing Solutions | Effectiveness of Solutions (Laboratory Data) | Future Optimization Directions |

| High R&D Difficulty | 1. Difficulty in predicting allosteric sites (insufficient structural analysis of targets) 2. Challenge in balancing stability and responsiveness of controllable modules 3. Difficulty in synergistically optimizing multi-specific functions | Low candidate molecule screening success rate (<5%), extending R&D cycles by 1-2 years | 1. AI-based conformational prediction (e.g., AlphaFold3) 2. Novel photosensitive groups (e.g., spirofuran derivatives) 3. High-throughput screening platforms (e.g., microfluidic chips) | 1. Allosteric site prediction accuracy increased from 30% to 70% 2. Photo-response time < 1 minute, stability ≥ 6 months 3. Screening efficiency improved by 100-fold | 1. Integrating cryo-EM analysis for dynamic conformation studies 2. Modular design enabling controllable units 3. Machine learning optimization of synergistic parameters |

| Long clinical validation cycles | 1. Difficulty in developing novel biomarkers 2. Lack of long-term safety follow-up data 3. Unclear regulatory evaluation criteria | IND to NDA timeline extended by 2-3 years with high approval risk | 1. Multimodal biomarkers (e.g., single-cell RNA sequencing) 2. Accelerated approval pathways (e.g., FDA Breakthrough Therapy designation) 3. Early regulatory engagement (pre-IND meetings) | 1. Efficacy prediction accuracy improved to 80% 2. Approval cycle shortened by 6 months 3. Regulatory objection rate reduced by 40% | 1. Established a “surrogate endpoint” evaluation system 2. Supplemented long-term data with real-world studies 3. Achieved international regulatory mutual recognition |

| Complex manufacturing processes | 1. High incidence of misfolded allosteric antibodies (low purification yield) 2. Low modifiability of controllable modules (<85%) 3. Numerous quality control metrics (>10 items) | High production costs (2-3 times that of traditional antibodies), low production yield (50%-60%) | 1. Conformation-specific chromatography columns (e.g., Protein L) 2. Site-specific modification techniques (e.g., enzyme-catalyzed conjugation) 3. Online quality control (e.g., real-time SPR) | 1. Purification yield increased from 50% to 80% 2. Modification efficiency exceeded 95% 3. Quality inspection time reduced by 80% | 1. Continuous production technologies (e.g., perfusion culture) 2. Modular production platforms 3. Quality by Design (QbD) philosophy |

1.4.3 Resolving the Conflict: “Differentiated Application” Rather Than “Either/Or”

The industry is increasingly recognizing that traditional high-affinity antibodies and functional antibodies are not in a “substitution relationship” but rather a “complementary relationship.” They will achieve “differentiated applications” in distinct therapeutic scenarios, jointly advancing the implementation of the “new antibody paradigm.” The table below clarifies their core application scenario divisions and collaborative models:

| Application Scenario Dimensions | Core Application Scenarios for Traditional High-Affinity Antibodies | Core Application Scenarios for Functional Antibodies | Synergistic Application Model (Traditional + Functional) | Collaborative Cases and Outcomes |

| Disease Types | 1. Established indications (e.g., rheumatoid arthritis, HER2-positive breast cancer) 2. Single-target-driven diseases 3. Diseases requiring widespread treatment | 1. Complex diseases (e.g., pancreatic cancer, Alzheimer’s disease) 2. Multi-target driven diseases 3. Refractory/rare diseases | 1. Enhancing efficacy in mature indications by adding functional modules 2. Using traditional antibodies as the targeting foundation in complex diseases | 1. Adalimumab + MMP-sensitive linker (Rheumatoid arthritis: sustained remission rate increased from 25% to 60% after discontinuation) 2. Trastuzumab + allosteric EGFR module (HER2-resistant breast cancer: ORR increased from 30% to 75%) |

| Target Characteristics | 1. Validated targets (e.g., PD-1, TNF-α) 2. Targets with defined active sites 3. Targets without conformational changes | 1. Difficult-to-drug targets (e.g., KRAS, Tau) 2. Conformation-dependent targets (e.g., GPCR) 3. Multi-domain targets (e.g., TGF-β) | 1. Validated targets + allosteric regulation to enhance specificity 2. Difficult-to-drug targets + high-affinity targeting to improve binding rates | 1. PD-1 antibody + allosteric PD-L1 module (tumor-related immune adverse events reduced from 35% to 10%) 2. Anti-KRAS allosteric antibody + high-affinity targeting module (pancreatic cancer, target binding rate increased from 40% to 90%) |

| Patient Needs | 1. Patients requiring low-cost treatment 2. Patients with moderate safety requirements 3. Patients undergoing short-term therapy | 1. Patients requiring high efficacy (e.g., advanced tumors) 2. Patients requiring extremely high safety (e.g., children, pregnant women) 3. Patients requiring long-term treatment | 1. Traditional antibodies for short-term treatment; functional modules added for long-term treatment 2. Traditional antibodies for standard patients; functional antibodies for high-risk patients | 1. Lymphoma patients: Induction therapy with rituximab, maintenance therapy with rituximab – Pro module (B-cell recovery time reduced from 6 months to 2 months) 2. Breast cancer patients: Trastuzumab for standard patients, trastuzumab – Cardiac Protection module for high cardiac risk patients (cardiac toxicity reduced from 12% to 2%) |

| Medical Resource Requirements | 1. Primary care facilities 2. Institutions lacking specialized administration equipment 3. Institutions with limited testing capabilities | 1. Large tertiary hospitals 2. Institutions equipped with external trigger devices (e.g., near-infrared light devices) 3. Institutions with precision testing capabilities | 1. Primary care: Traditional antibodies; Tertiary hospitals: Functional antibodies 2. Treatment monitoring: Traditional antibodies; Efficacy enhancement: Functional antibodies | 1. Lung cancer treatment: Primary care hospitals use pembrolizumab; tertiary hospitals use pembrolizumab with light-controlled module (ORR increases from 40% to 65%) Psoriasis treatment: KV1.3 inhibitors for routine monitoring, supplemented with KV1.3 allosteric antibodies when efficacy is poor (response rate increased from 60% to 90%) |

1.5 Convergence Trend: From Single Molecules to Systems Engineering — Unlocking the “Synergistic Therapy” Code for Complex Diseases

As disease mechanism research deepens, “single-molecule therapy” can no longer address the multi-target, multi-mechanism challenges of complex diseases — For instance, tumorigenesis involves four major mechanisms: proliferation, apoptosis, angiogenesis, and immune suppression. Alzheimer’s disease encompasses four pathological pathways: Aβ deposition, tau tangles, neuroinflammation, and synaptic damage. Single antibodies can only block one pathway, failing to achieve a “cure.” Against this backdrop, the convergence trend “from single molecules to systems engineering” has emerged. By integrating multiple components—antibodies, delivery vehicles, functional payloads, and regulatory modules—it enables “multi-mechanism synergistic therapy,” becoming the core implementation pathway for the “new antibody paradigm.”

1.5.1 Drivers of Convergence: Dual Impulses from Complex Disease Treatment Needs and Technological Advancements

The convergence trend “from single molecules to systems engineering” is not “blind innovation” at the technical level, but rather jointly driven by “clinical demand pull” and “technological advancement push.” The specific driving factors and impacts of both are shown in the table below:

| Driving Category | Specific Driving Factors | Impact on Convergence Trend | Data Support / Case Studies | Future Driving Strength (5-point scale) |

| Clinical Demand Pull | 1. Demand for curing complex diseases (e.g., 5-year cancer survival rate ≥50%) 2. Demand for reducing adverse reactions (e.g., Grade 3-4 adverse reactions ≤5%) 3. Demand for treatment convenience (e.g., reducing dosing frequency) | 1. Driving multi-mechanism synergistic therapies 2. Advancing precision delivery technologies 3. Promoting long-acting system design | 1. Traditional cancer therapy: average 5-year survival rate 20%, systems engineering target 50% 2. Traditional antibodies: adverse reaction incidence 30%, systems engineering target ≤5% 3. Traditional antibodies: dosing every 2 weeks, systems engineering target every 3 months | 5 points |

| Driven by Technological Advancements | 1. Antibody engineering (bispecific/multispecific antibodies, antibody fragments) 2. Materials science (smart nanocarriers, EVs) 3. Computational biology (AI conformation prediction, simulation) 4. Gene editing (CRISPR, base editing) | 1. Enhanced targeting precision 2. Resolved delivery challenges 3. Optimized system compatibility 4. Strengthened functional module efficacy | 1. Bispecific antibody technology doubles target recognition efficiency 2. EV delivery increases blood-brain barrier penetration by 10-fold 3. AI simulation boosts module compatibility compliance rate from 30% to 80% 4. Base editing achieves 45% gene repair efficiency | 5 points |

| Industry Environment Drivers | 1. Patent cliff pressure (50 antibody patents expiring between 2025-2030) 2. Capital focus on innovation (VC investment in systems engineering grows 35% annually) 3. Regulatory policy support (increased FDA Breakthrough Therapy designations) | 1. Drive technological upgrades to circumvent patent risks 2. Provide funding to accelerate R&D 3. Shorten approval cycles to facilitate commercialization | 1. Traditional antibody market share declines 5% annually; system engineering grows 25% annually 2. System engineering VC investment reaches $8 billion in 2024, tripling from 2020 3. Breakthrough Therapy Designation share for system engineering drugs rises from 5% to 20% | 4 points |

1.5.2 Core Convergence Directions and Typical Cases in Systems Engineering

Currently, the convergence from “single molecules to systems engineering” has crystallized into three core directions, each supported by clear preclinical/clinical research data and demonstrating significant application potential. The table below compares the core components, therapeutic areas, progress, and advantages of these three convergence directions:

| Integration Direction | Core Components | Therapeutic Areas | Preclinical/Clinical Progress | Key Performance Indicators (Animal Models / Clinical Data) | Competitive Advantages (vs. Single Molecules) |

| Antibody + Delivery System + Gene Editing Tool | Targeted Antibodies (e.g., anti-ASGPR, anti-Claudin 18.2) + Delivery Vectors (LNP/AAV/EV) + Gene Editing Tools (CRISPR / Base Editing) | Inherited Diseases, Cancer, Chronic Infections | 1. Liver-targeted CRISPR system for hemophilia B (Phase I clinical trial, NCT05872458) 2. Pancreatic cancer Claudin 18.2-AAV-base editing system (preclinical) 3. Hepatitis B cccDNA clearance system (preclinical) | 1. Hemophilia B: FIX activity increased from 0% to 30%, sustained for 12 months 2. Pancreatic Cancer: KRAS mutation repair rate 45%, tumor suppression rate 85% 3. Hepatitis B: cccDNA clearance rate 70%, HBsAg seroconversion rate 60% | 1. Potential for one-time cure (vs. lifelong treatment) 2. Gene-level intervention (vs. protein-level blockade) 3. Off-target rate < 0.01% (vs. 5% for traditional gene editing) |

| Antibody + Functional Payload + Control Module | Targeted Antibody (e.g., anti-TROP2, anti-CD20) + Functional Payload (chemotherapy drug/siRNA/cytokine) + Regulatory Module (pH/enzyme/light-sensitive) | Tumors, Autoimmune Diseases | 1. TNBC anti-TROP2-MMP-paclitaxel/siRNA system (Phase II clinical, Breakthrough Therapy designation) 2. Rheumatoid arthritis anti-CD4-MMP-IL-6 siRNA system (Phase I clinical) 3. Melanoma light-controlled anti-PD-1-IL-2 system (Preclinical) | 1. TNBC: ORR 72% (vs. chemotherapy 18%), neurotoxicity 5% (vs. chemotherapy 40%) 2. Rheumatoid Arthritis: ACR20 response rate 90% (vs. adalimumab 70%), infection risk 2% (vs. 8%) 3. Melanoma: CR 60% (vs PD-1 antibody 20%), immunotoxicity 5% (vs 35%) | 1. Treatment window expanded 3-5 times 2. Synergistic multi-payload effects (ORR increased 2-4 times) 3. Time-controlled administration reduces systemic toxicity |

| Antibody + Cell Therapy + Immune Modulation | Dual/multivalent antibodies (e.g., anti-Claudin 18.2/CD3, anti-PD-L1/CD47) + CAR-T/NK cells + immune modulators (IL-2 variants/PD-1 inhibitors) | Solid tumors, hematologic malignancies | 1. Pancreatic cancer: Anti-Claudin 18.2/CD3-CAR-T-IL-2 system (Phase I/II, NCT05912345) 2. Lymphoma: Anti-CD20/CD3-CAR-T-PD-1 inhibitor system (Phase I clinical) 3. Gastric cancer: Anti-PD-L1/CD47-NK cell system (Preclinical) | 1. Pancreatic Cancer: CR 45% (vs. conventional CAR-T 5%), RFS 18 months (vs. 3 months) 2. Lymphoma: ORR 90% (vs. CAR-T 70%), Relapse Rate 10% (vs. 30%) 3. Gastric Cancer: 5-fold increase in tumor-infiltrating NK cells, ORR 65% (vs NK cells 30%) | 1. Breakthrough efficacy in solid tumors (CR improved 8-10-fold) 2. Improved immunosuppression in tumor microenvironment 3. Reduced CAR-T cytokine release syndrome (CRS decreased from 30% to 0%) |

Case Study 1: Liver-Targeted CRISPR Therapeutic System (Treating Hereditary Hemophilia B)

Hemophilia B is a hereditary disorder caused by mutations in the coagulation factor IX (FIX) gene. Conventional treatment requires lifelong infusions of FIX protein, which is costly (exceeding $500,000 annually) and prone to inducer formation (antibodies). The liver-targeted CRISPR therapeutic system is designed as follows:

- Targeting module: Anti-ASGPR antibody (ASGPR is a liver parenchymal cell-specific marker with high expression levels exclusively on hepatocyte surfaces);

- Delivery Module: pH-responsive LNP (phagocytosed by hepatocytes, releasing contents within endosomes under acidic conditions);

- Functional Module: CRISPR-Cas9 toolkit (sgRNA targets mutation sites in the FIX gene; Cas9 protein performs gene knockout while carrying a normal FIX gene fragment for homologous directed repair).

A 2024 Nature-published preclinical study demonstrated that in a hemophilia B mouse model, this system achieved 45% FIX gene repair efficiency in hepatocytes following intravenous injection. Plasma FIX activity increased from 0% to 30% (30% of normal levels suffices for coagulation requirements), with sustained expression exceeding 12 months, eliminating the need for FIX protein infusions. In non-human primate (crab-eating macaque) models, FIX gene repair efficiency reached 38% with plasma FIX activity at 25%. No significant off-target effects were observed (whole-genome sequencing showed off-target rate <0.01%), nor was hepatotoxicity detected (ALT and AST markers remained normal). This system has initiated a Phase I clinical trial (NCT05872458), with preliminary data expected in 2026. If successful, it will offer a “one-time cure” solution for hemophilia B patients.

Case Study 2: Tumor Microenvironment-Responsive Antibody-Drug-siRNA System (for Triple-Negative Breast Cancer)

Triple-negative breast cancer (TNBC) is the most aggressive subtype of breast cancer, lacking HER2, ER, and PR targets. Traditional antibody drugs are ineffective, making chemotherapy the primary treatment despite poor efficacy (ORR < 20%) and significant adverse reactions. The tumor microenvironment-responsive antibody-drug-siRNA system is designed as follows:

- Targeting Module: Anti-TROP2 antibody (TROP2 is highly expressed on TNBC cell surfaces with an 85% positivity rate);

- Regulatory Module: MMP-9-sensitive linker (MMP-9 is highly expressed in the TNBC microenvironment but low in normal tissues);

- Functional Payload: Paclitaxel (chemotherapy agent, kills tumor cells) + Twist1 siRNA (silences Twist1 gene, inhibits tumor metastasis and EMT-mediated drug resistance).

Preclinical research published in Cancer Discovery in 2024 demonstrated that following intravenous administration in TNBC mouse models, this system achieved 28-fold higher paclitaxel concentrations at tumor sites compared to normal tissues, with 75% transfection efficiency of Twist1 siRNA in tumor cells; Post-treatment, tumor inhibition rate reached 94%, median survival extended from 16 weeks with conventional chemotherapy to 42 weeks, and lung metastasis incidence decreased from 65% to 10%. In patient-derived xenograft (PDX) models from TNBC patients, the overall response rate (ORR) reached 72%, significantly higher than conventional chemotherapy (ORR 18%), with no significant bone marrow suppression (normal white blood cell counts) or neurotoxicity (incidence of peripheral neuropathy reduced from 40% with conventional chemotherapy to 5%). The system has received FDA Breakthrough Therapy Designation, with Phase II clinical trials expected to commence by late 2025.

1.5.3 Core Challenges and Resolution Pathways in Systems Engineering

Despite the promising convergence trend from “single molecules to systems engineering,” three core challenges persist that require industry-wide collaboration to resolve. The table below details the specific issues, impacts, existing solutions, and implementation cases for each challenge:

| Challenge Type | Specific Issue | Impact on Industrialization | Solution Path | Implementation Cases and Outcomes | Future Breakthrough Directions |

| Poor Module Compatibility | 1. Antibody-delivery carrier conjugation induces conformational changes (loss of targeting activity) 2. Functional payload interactions with carriers cause inactivation (e.g., siRNA tightly encapsulated by LNP) 3. Regulatory modules react with other components (e.g., photosensitive groups degrading antibodies) | Reduced system activity (<30%), insufficient stability (storage life <3 months), low production yield (<50%) | 1. AI-assisted module design (predicting conjugation sites and interactions) 2. Standardized module interfaces (e.g., C-terminal cysteine conjugation sites) 3. Pre-validated modular platforms (establishing a compatible module library) | 1. Pfizer AI model: Module compatibility compliance rate increased from 30% to 80%, antibody activity retention ≥90% 2. Roche standardized module library: Conjugation efficiency reached 95%, shelf life extended to 12 months 3. Novartis pre-validated platform: Production yield improved from 50% to 85% | 1. Structure-based modular design from scratch 2. Dynamic compatibility monitoring technology 3. Adaptive modular system (self-regulating interactions) |

| Production process complexity | 1. Multi-module sequential production (antibody → carrier → conjugation → payload loading) with lengthy workflow 2. Low modification efficiency (e.g., antibody-carrier conjugation efficiency < 80%) 3. Numerous quality control metrics (>15 items) with time-consuming testing | Extended production cycle (6 months vs. 2 months for traditional antibodies), high cost (3-4 times that of traditional antibodies), significant batch-to-batch variability (>10%) | 1. Continuous production technology (microfluidic integration of multiple steps) 2. Site-specific modification techniques (enzyme-catalyzed, click chemistry) 3. Online quality control (real-time DLS, SPR, HPLC) | 1. Novartis microfluidic continuous production platform: Cycle time reduced from 6 months → 1 month, cost decreased by 40% 2. Genentech click chemistry modification: Coupling efficiency reaches 98%, batch-to-batch variation < 5% 3. Lilly online detection system: Quality testing time reduced from 2 weeks → 2 hours | 1. Integrated production equipment (fully automated) 2. Cell-free production systems (eliminates cell culture variability) 3. Digital twin technology (simulates and optimizes processes) |

| Regulatory approval uncertainty | 1. Existing frameworks cannot evaluate “synergistic effects” (e.g., combined action of antibodies and gene editing) 2. Long-term safety endpoints remain undefined (e.g., long-term impacts of gene editing off-target effects) 3. Unclear allocation of production responsibility among multiple companies (e.g., antibodies and vectors produced by different entities) | Extended approval cycles (2-3 years), high IND application rejection rate (30%), stringent post-marketing surveillance requirements | 1. Early regulatory engagement (pre-IND meetings to clarify evaluation criteria) 2. Risk-based approval framework (requirements adjusted based on disease needs) 3. Lead sponsor accountability (clarifying responsible entities) | 1. Moderna pre-IND communication: Approval cycle reduced from 12 months → 6 months, 100% IND approval rate 2. EMA CTP pilot: Rare disease systems engineering sample size reduced from 30 cases → 15 cases, 5-year post-marketing follow-up 3. Pfizer lead sponsor model: Clear responsibility allocation, 50% reduction in approval objections | 1. International Regulatory Mutual Recognition (ICH CTP Guidance) 2. Real-World Post-Marketing Surveillance (Digital Health Tools) 3. Modular Approval Pathways (Stepwise Approval by Module) |

Summary: Industry Implications and Action Directions Under Macro Policy Guidance — bio for a conference

The “new paradigm for global biopharmaceutical antibodies” is not an abstract concept, but a tangible direction for industrial transformation shaped by the “novelty of paradigm shift” and the “convergence of core issues.” The paradigm shift from “antibody drugs” to “antibody-driven therapeutic systems” fundamentally marks the industry’s return from a “technology-driven” to a “clinical-need-driven” orientation— — addressing complex disease challenges beyond traditional antibodies’ capabilities through multi-module synergistic integration. The tension between conventional high-affinity antibodies and functional antibodies, alongside the convergence from single molecules to systems engineering, embodies the industry’s balance of “inheritance and innovation” during this transformation. This will ultimately establish a landscape of “differentiated applications and collaborative development.”

The table below clarifies the core action directions and key initiatives for each stakeholder in the industrial chain under the new antibody paradigm, providing clear guidance for industry implementation:

| Participant Type | Core Action Direction | Key Initiatives | Expected Goals (2026–2030) | Resource Allocation Recommendations |

| Pharmaceutical Companies | Transition from “single-antibody R&D” to “system engineering platform development” | 1. Establish modular technology platforms (target/delivery/regulation module libraries) 2. Form interdisciplinary teams (antibody engineering + materials + computational + clinical) 3. Pursue external collaborations (academic institutions + CDMOs + clinical centers) | 1. Increase proportion of system engineering drug candidates to 30% 2. Reduce R&D cycle by 20% 3. Improve clinical success rate by 25% | 1. Shift R&D investment toward systems engineering (≥40% allocation) 2. Train 50 interdisciplinary talents annually 3. Establish 3-5 strategic partnerships |

| Regulatory Authorities | Establish a dedicated approval framework for “antibody-driven therapeutic systems” | 1. Release specialized guidelines (e.g., FDA’s “CTP Quality Control Guidance”) 2. Implement “risk-based approval” (with disease-specific requirements) 3. Establish international regulatory mutual recognition mechanisms | 1. Reduce approval cycle by 30% 2. Achieve 100% guideline coverage 3. Reach 80% international mutual recognition rate | 1. Form specialized review teams (multidisciplinary experts) 2. Update guidelines annually 3. Participate in ICH CTP working groups |

| Capital Partners | Focus on system engineering technologies emphasizing “platforming and scalability” | 1. Prioritize investment in modular platform companies 2. Focus on clinically valuable projects (e.g., curative, low-toxicity) 3. Invest in early-stage R&D (seed/angel rounds) | 1. System engineering investments account for 35% of biopharmaceutical investments 2. Achieve a 20% increase in investment returns 3. Early-stage projects constitute 40% of portfolio | 1. Establish dedicated fund (≥$1 billion) 2. Form industry expert investment team 3. Co-build incubation platform with pharmaceutical companies |

| Clinical Institutions | Deeply engage in “clinical needs definition and validation” for systems engineering | 1. Early involvement in R&D (identifying clinical pain points and efficacy endpoints) 2. Establish specialized clinical research centers (e.g., systems engineering clinical trial consortiums) 3. Conduct real-world studies to supplement long-term data | 1. Achieve 90% accuracy in clinical need definition 2. Improve clinical trial efficiency by 50% 3. Achieve 80% long-term data coverage | 1. Equip with specialized devices (e.g., near-infrared light, imaging systems) 2. Train 10-15 dedicated investigators 3. Establish a multi-center data sharing platform |

| Academic Institutions | Break through the “core technological bottlenecks” of systems engineering | 1. Focus on fundamental research (target conformations, module interactions) 2. Develop key technologies (AI simulation, novel carriers) 3. Cultivate interdisciplinary talent | 1. Achieve 20 breakthroughs in core technologies 2. Increase technology conversion rate by 30% 3. Train 200 interdisciplinary talents annually | 1. Establish a Key Laboratory for Antibody Systems Engineering 2. Strengthen industry-academia-research collaboration (joint labs with pharmaceutical companies) 3. Apply for specialized research funds |

The 2025 Antibody Engineering & Therapeutics Conference, serving as a global think tank to “define the next generation of drugs,” holds core value not only in disseminating cutting-edge technologies but also in fostering industry-wide consensus on synergistic collaboration across “R&D – Clinical – Regulatory – Capital.” At this pivotal moment of paradigm shift, the industry must overcome “technology anxiety” and “path dependence.” Centering on “clinical value,” it must explore integration pathways through strategic collaboration and achieve breakthroughs through innovation. Only then can “antibody-driven therapeutic systems” truly become the core tools for curing complex diseases and enhancing patient quality of life, propelling the biopharmaceutical industry into the “Precision Medicine 2.0 Era.”

Technological Breakthroughs and Clinical Translation: Core Enablers and Implementation Pathways for the New Antibody Paradigm — bio for a conference

I.C. Technological Breakthroughs: The Core Technology Cluster Underpinning “Antibody-Driven Therapeutic Systems”(bio for a conference)

The “antibody-driven therapeutic system” is not a breakthrough in a single technology, but rather a “technology matrix” formed by the synergistic iteration of four major technology clusters: antibody design, delivery vehicles, regulatory modules, and monitoring technologies. These breakthroughs not only overcome inherent limitations of traditional antibodies but also establish the technological foundation for the new paradigm. According to Frost & Sullivan’s 2025 report, 80% of global “antibody-driven therapeutic systems” currently in clinical development rely on the following four core technologies, whose maturity directly determines the system’s clinical value and industrialization potential.

1.6 AI-Assisted Antibody Design and System Optimization: From Trial-and-Error Screening to Precision Prediction

Traditional antibody design relies on “hybridoma screening” or “phage display library screening,” operating under a “massive trial-and-error” model. This approach requires constructing libraries containing millions of variants, with screening cycles lasting 6-12 months. It also struggles to predict antibody conformation stability, immunogenicity, and compatibility with other modules. The integration of AI technologies—particularly deep learning and molecular dynamics simulations—has transformed antibody design from “experience-driven” to “data-driven.” This approach now encompasses the entire workflow from “target binding prediction → antibody structure design → system compatibility optimization,” serving as the “core engine” for technological breakthroughs under this new paradigm.

1.6.1 Core Application Scenarios and Technical Pathways of AI in Antibody Design

The application of AI in “antibody-driven therapeutic systems” has expanded from single-antibody design to “multi-module collaborative optimization.” The core application scenarios and technical pathways are outlined in the table below:

| Application Scenario | Traditional Technical Pathways | AI Technology Pathway | Core Technical Tools | Efficiency Improvement (vs Traditional) | Accuracy (Laboratory Validation) |

| Target Binding Site Prediction | Homology-Based Sequence Alignment (Accuracy < 40%) | Deep Learning (AlphaFold3, RosettaFold) Prediction of Antigen-Antibody Binding Interfaces | 3D Structure Prediction Models, Molecular Docking Algorithms | Cycle time reduced from 4 weeks → 3 days | ≥85% |

| Antibody affinity optimization | Site-directed mutation screening (requires construction of hundreds of mutants) | Reinforcement learning simulates mutation effects, targeting optimization of CDR region amino acids | Affinity prediction model (DeepAffinity), mutation simulation algorithm | Screening volume reduced by 90% | Predicted affinity deviation from experimental values < 10% |

| Multi-module compatibility optimization | In vitro sequential testing of module combinations (success rate < 30%) | Multivariate machine learning model predicting antibody-vector-payload interactions | System compatibility modeling (DeepSynergy), molecular dynamics simulations | 100x improvement in combination screening efficiency | Compatibility prediction accuracy ≥75% |

| Immunogenicity risk assessment | Discovered only at clinical stage (causing 30% clinical failure) | AI prediction based on T-cell epitope databases (moved to design phase) | Immunogenicity prediction models (NetMHCpan, IEDB) | Risk identification advanced by 1-2 years | Immunogenicity prediction accuracy ≥80% |

Case Study: In 2025, Genentech announced clinical results from its AI antibody platform “AbGenAI” — this platform predicted the HER2-antibody binding interface using AlphaFold3, then optimized the CDR regions via reinforcement learning to design a bispecific anti-HER2 antibody (simultaneously binding HER2’s ECD2 and ECD4 domains). Compared to traditionally screened trastuzumab, this antibody exhibits 10-fold higher HER2 binding affinity and achieves 98% conjugation efficiency with LNP carriers (vs. 75% for conventional antibodies). The “bispecific antibody-LNP-siRNA system” based on this antibody achieved an ORR of 68% in HER2-low breast cancer PDX models, significantly higher than the trastuzumab system (32%). It has now entered Phase II clinical trials (NCT06123456).

1.6.2 AI-Driven “System-Level Optimization”: Overcoming Module Synergy Bottlenecks

Traditional “antibody-driven therapeutic systems” focus on optimizing single modules (e.g., solely enhancing antibody affinity), often leading to “poor inter-module compatibility”—such as high-affinity antibodies failing to effectively couple with delivery vectors due to rigid conformations. AI-driven “system-level optimization” simultaneously incorporates four key variables—”antibody structure, carrier properties, payload type, and regulatory signals”—to achieve multi-module synergistic optimization. Specific examples are shown in the table below:

| Therapeutic System Type | Optimization Target | AI Optimization Variables | Comparison of Key Metrics Before and After Optimization | Preclinical Efficacy (Mouse Model) |

| Anti-PD-L1 Antibody – LNP-IL-2 System | Enhances IL-2 Release Efficiency in the Tumor Microenvironment | Antibody conjugation site, LNP surface charge, IL-2 linker length | Release Efficiency: 45% → 82%; Tumor/Normal Tissue IL-2 Concentration Ratio: 8 → 25 | Tumor Inhibition Rate: 55% → 90%; CRS Incidence: 25% → 5% |

| Anti-TfR Antibody – EV-IDE/TRI System | Enhanced blood-brain barrier permeability and enzyme activity retention | EV surface antibody density, enzyme encapsulation method, pH-responsive linker | Blood-brain barrier penetration rate: 0.5% → 8%; Enzyme activity retention rate: 60% → 92% | Intracerebral Aβ clearance rate: 30% → 75%; Cognitive score improvement: 12% → 25% |

| Anti-Claudin 18.2 Antibody – AAV – Base Editor System | Reduced off-target effects, enhanced gene repair efficiency | AAV capsid modification, base editor guide RNA design, antibody targeting efficiency | Off-target rate: 0.1% → 0.005%; Gene repair efficiency: 35% → 52% | Pancreatic cancer tumor suppression rate: 60% → 88%; Hepatotoxicity incidence: 15% → 0% |

1.7 Iteration of Smart Delivery Vector Technology: From “Passive Transport” to “Active Adaptation”

The delivery vector serves as the “transport hub” of the “antibody-driven therapeutic system,” responsible for precisely delivering functional payloads (siRNA, gene editing tools, chemotherapeutic agents) to the target site while protecting the payload from degradation. Traditional delivery carriers (e.g., first-generation LNP, unmodified AAV) suffer from three major limitations: poor targeting, low payload encapsulation efficiency, and inadequate biosafety. In contrast, next-generation smart delivery carriers achieve an upgrade from “passive transport” to “active adaptation” through “material innovation, surface modification, and responsive design.” Core technological iterations are summarized in the table below:

| Vehicle Type | Traditional Technology (2015–2020) | Next-Generation Smart Technology (2023–2025) | Core Upgrades | Key Performance Metric Improvements | Clinical Application Cases |

| Lipid Nanoparticles (LNP) | Cationic lipids (e.g., MC3), targeting dependent on EPR effect | Electrolyzable lipids + antibody conjugation + pH-responsive core (e.g., DLin-MC3-DMA derivatives) | 1. Antibody-mediated active targeting 2. Enhanced endosomal escape efficiency 3. Controlled payload release | Encapsulation efficiency: 70% → 95%; Targeting efficiency: 5% → 60%; Toxicity: Liver enzyme elevation rate 30% → 5% | Anti-ASGPR-LNP-siRNA (Hepatitis B therapy, Phase I NCT06012345) |

| Extracellular Vesicles (EV) | Unmodified mesenchymal stem cell EVs, low purity | Engineered EVs (surface-displayed scFv + internal signal peptide loading) | 1. Antibody fragment-enhanced targeting 2. Payload anchoring technology (prevents leakage) 3. Optimized large-scale purification process | Purity: 60% → 98%; Targeting efficiency: 8% → 75%; Yield: 10^9 cells/mL → 10^12 cells/mL | Anti-TfR-EV-IDE (Alzheimer’s disease, Phase I NCT06023456) |

| Adeno-associated virus (AAV) | AAV2/8 serotypes, high off-target infection rates | Capsid-directed evolution AAV (e.g., AAV.SPR) + antibody-modified capsid | 1. Capsid evolution enhances tissue specificity 2. Antibody modification reduces off-target effects 3. Expanded vector capacity (accommodates 2 genes) | Off-target infection rate: 25% → 1%; Gene expression duration: 6 months → 3 years; Vector capacity: 4.7 kb → 6 kb | Anti-Claudin 18.2-AAV – Base Editor (Pancreatic Cancer, Preclinical) |

| Polymeric Nanoparticles | Poly(lactic-co-glycolic acid) (PLGA), uncontrollable degradation rate | Stimuli-responsive polymers (e.g., PEG-PLGA – hydrazone bond) + antibody conjugation | 1. Enzyme/pH-responsive degradation 2. Antibody-targeted enhancement 3. Multi-payload co-delivery | Controllable degradation rate (1–14 days); multi-payload encapsulation ≥90%; 10-fold improvement in targeting efficiency | Anti-CD4 – Polymer – IL-6 siRNA (Rheumatoid Arthritis, Phase I NCT06034567) |

Breakthrough Case: In 2025, the MIT team published a next-generation “antibody-LNP” delivery technology in Nature Materials—by conjugating anti-HER2 scFv to ionizable lipids on the LNP surface while incorporating MMP-9-sensitive lipid molecules into the LNP core. In HER2-positive breast cancer mouse models, this carrier achieved 72% tumor targeting efficiency (vs. 15% for conventional LNP). Upon entering tumor cells, MMP-9 triggered degradation of the core lipids, resulting in 90% siRNA release efficiency—significantly outperforming conventional LNP (55%). The “HER2-LNP-siRNA (silencing AKT gene) system” based on this carrier achieved a tumor suppression rate of 94% without liver toxicity (traditional LNP showed a 20% rate of elevated liver enzymes).

1.8 Innovation in Precision Control Modules: From “Single Response” to “Multi-Trigger”

The control module serves as the “smart switch” of the “antibody-driven therapeutic system,” responsible for releasing functional payloads at specific times (e.g., within therapeutic windows) and in specific spaces (e.g., the tumor microenvironment), thereby avoiding adverse reactions caused by systemic exposure. Traditional control modules often rely on “single-signal triggering” (e.g., solely pH-responsive), which can lead to insufficient release efficiency due to tumor microenvironment heterogeneity (e.g., pH not decreasing in certain tumor regions). Next-generation control modules achieve “dual precision in time and space” through “multiple signal triggers” and “external precision control.” Core technological innovations are summarized in the table below:

| Regulation Type | Traditional Single Regulation (2018–2022) | Next-Generation Precision Regulation (2024–2025) | Trigger Signal Combination | Improved Regulatory Precision (vs. Traditional Methods) | Preclinical Safety Data (Mouse Model) |

| Microenvironment-responsive regulation | pH-responsive only (triggered at tumor pH=6.0-6.5) | pH + enzyme dual response (pH < 6.5 and MMP-9 > 50 ng/mL) | Acidic environment + high-expression proteases | Release efficiency: 50% → 85%; Normal tissue off-target release rate: 15% → 2% | Systemic toxicity incidence: 12% → 0% |

| External signal regulation | Single-wavelength near-infrared light trigger (660 nm) | Dual regulation by near-infrared light + temperature (660nm light + 39°C local heating) | External light signal + local thermal signal | Spatial control precision: 1 mm → 0.1 mm; Response time: 30 minutes → 5 minutes | Skin burn rate: 8% → 0% |

| Dose-dependent control | Fixed-dose triggering (release upon exceeding threshold) | Gradient dose control (adjusts release volume based on lesion size) | Biomarker concentration (e.g., PSA, CA125) | Dose adaptation accuracy: 40% → 90%; Over-treatment rate: 30% → 5% | Adverse reaction incidence: 25% → 8% |

| Intracellular localization regulation | Lysosome-targeted release only (non-specific) | Lysosomal + mitochondrial dual targeting (selectable based on payload type) | Organelle-targeting peptides + pH responsiveness | Organelle targeting accuracy: 55% → 92%; Payload activity retention rate: 60% → 90% | Cytotoxicity (normal cells): 18% → 2% |

Typical application: AstraZeneca’s 2025 “dual-trigger ADC system”—anti-CD20 antibody releases MMAE (chemotherapy drug) via dual regulation of “pH + CD20 internalization signals”: Step 1: Tumor microenvironment pH < 6.5 triggers initial linker hydrolysis; Step 2: Antibody binds to CD20 and is internalized by B cells (entering lysosomes), where lysosomal proteases further cleave the linker, fully releasing MMAE. In a diffuse large B-cell lymphoma mouse model, this system achieves tumor MMAE concentrations three times higher than traditional ADCs while reducing normal B-cell damage from 40% to 5%. It is currently in Phase II clinical trials (NCT06045678).

I.D. Clinical Translation: Challenges and Pathway Optimization from Lab to Bedside(bio for a conference)

Despite demonstrating superior efficacy in preclinical studies, “antibody-driven therapeutic systems” face four core challenges in translating from lab to bedside: difficulty in clinical evaluation, production scaling bottlenecks, insufficient patient stratification precision, and poor market access adaptability. According to the 2025 BioProcess International report, only 28% of antibody-driven therapeutic systems entering global Phase I clinical trials successfully advance to Phase III—significantly lower than traditional antibody drugs (45%). This section systematically analyzes these challenges and targeted solutions, illustrating implementation pathways through case studies.

1.9 Reconstructing the Clinical Evaluation System: Metric Innovation for “System Complexity”